NANT XL System

Full automation, built-in microscope with confluency estimation, remote continuous monitoring: the key features for a successful and traceable cell production. Sophysticated technology made simple thanks to the distinctive features of NANT Automated Cell Culturing Systems.

Smart Process Monitoring

All key process parameters as Temperature, CO2 mixture percentage and Cell Confluency always displayed on user interface. An intuitive, smart depicting of the current protocol phase: everything at your fingertips.

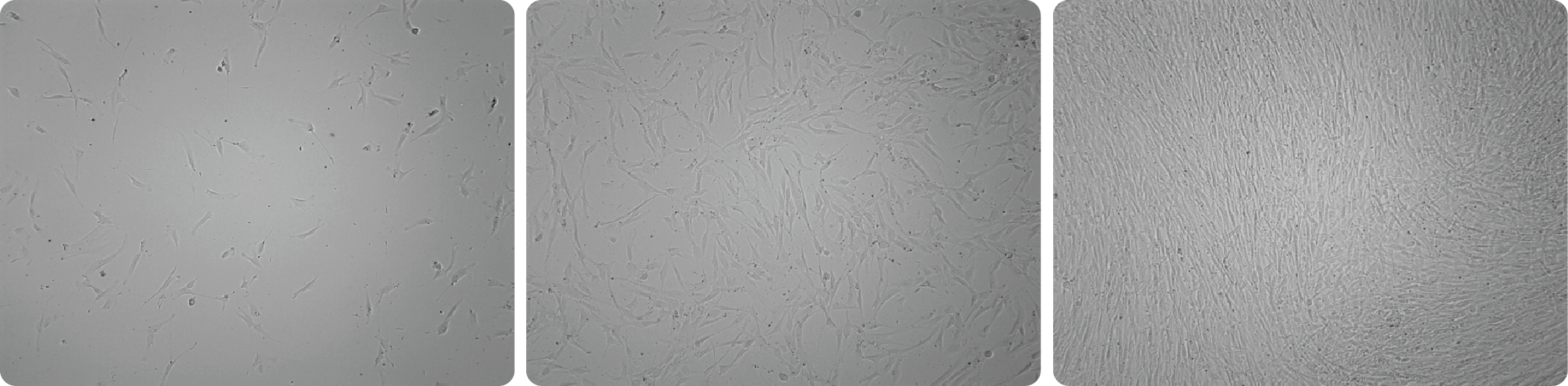

Unique Microscopic Imaging and Cell Confluency Estimation

The built-in auto-focus microscopic imaging automatically acquires and calculates Cell Confluency. The ideal feature to identify the optimal timeframe for cell harvesting - or just to see cells growing in real-time.

Subculturing, Automatically

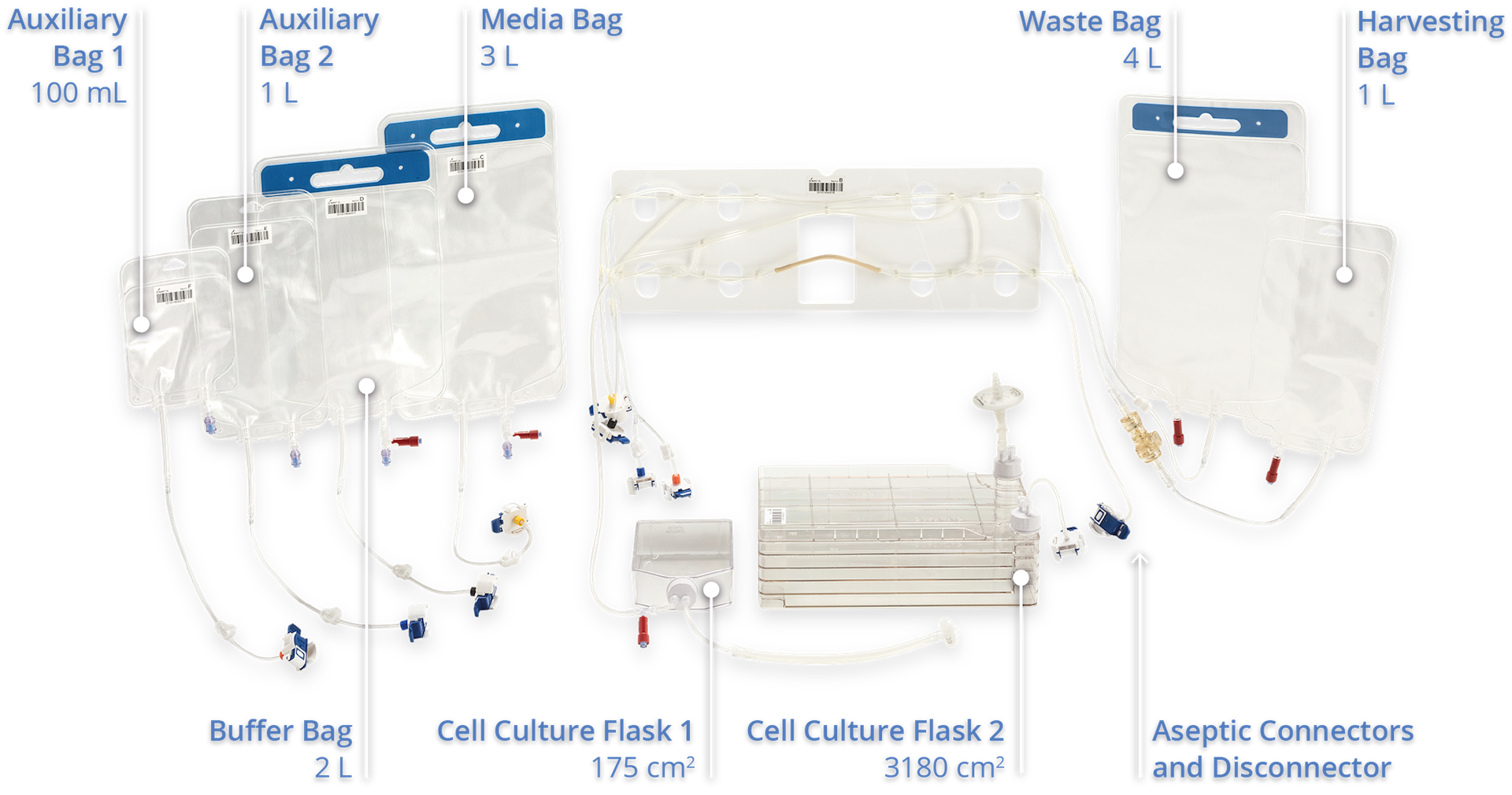

Automated subculturing from an initial 175 cm2 flask to a subsequent 3180 cm2, 5-layered container. A competitive feature allowing to obtain large amounts of expanded cells even from small quantities of starting material.

Aseptic Connections, in Seconds

As in all NANT Automated Cell Culturing Systems, the different sections of NANT XL Cartridge are designed to be quickly and easily connected and disconnected - when required - thanks to the integration of validated aseptic connectors and disconnectors.

NANT XL Cartridge

A success story: components you already know, engineered in an easy-to-load, disposable, closed system for safe and cGMP-compliant cell processing.

Traceability of Disposables and Users

Process traceability is granted by barcode identification of both NANT XL Cartridge components and Users actively involved in any critical operations or process changes and decisions.

Remote Monitoring

Special Web Application allows full, real-time remote monitoring of in-process control information. No expensive and time-consuming personnel access to the cell room required.

Traceability of Operations

The Cell Culture Report is a fully automated recording of any events occurred during the process with NANT XL System, downloadable as PDF. It can be used to track process compliance and is easily integrable in any QMS as an auditable document. See example.

Ready for Downstream Processing

NANT XL System output is a cell suspension in a bag, ready for virtually any kind of required downstream processing operations, including those that require welding to other reagents-containing bags too.

Example of Mesenchymal Stem Cell Expansion with the NANT XL System

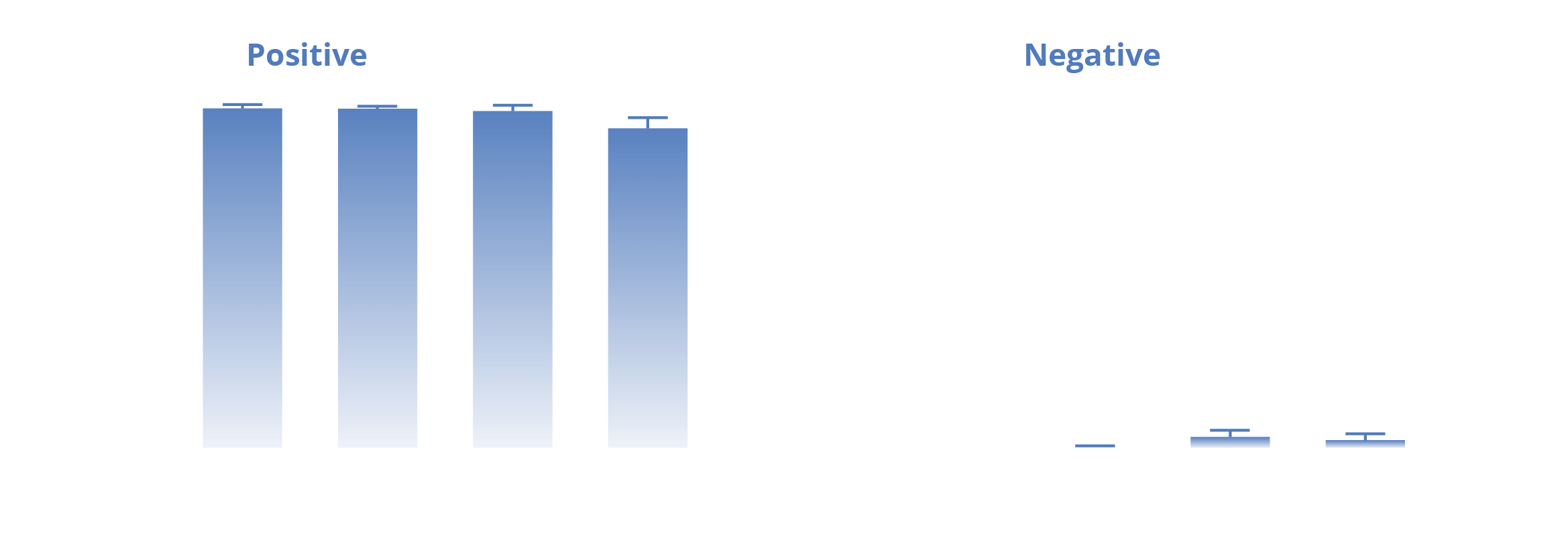

| Amount of starting material | Days of culture | Cell Culture Surface (cm2) | No. of cells harvested | Density of harvested cells (no. of cells/cm2) | Viability of harvested cells (%) |

|---|---|---|---|---|---|

| 1x106 pre-expanded MSCs | 8 ± 1 | 175 cm2 to 3180 cm2 5 layers flask |

2.72 x 108 ± 2.55 x 107 |

8.56 x 104 ± 8.00 x 103 |

96.0 |

Representative images of MSCs taken by the NANT XL System during cell culture

Benefits

cGMP-compliance, Scale Out and Cost Efficiency. Enabling the transition from your manual protocol to an automated process. Learn more ⟩

Technology

Empowering your ATMP manufacturing with Automation, Flexibility, Integrated Imaging and Remote Monitoring. Learn more ⟩

We're Ready to Support You

The system flexibility and adaptability permit efficient workflow automation for multiple cell-based and cell-derived product manufacturing processes.

Customer-specific cell expansion protocols can be rapidly automated in NANT XL with ease! Contact us for further information and opportunities.